Roof Coating

GA Roofing & Repair, Inc., headquartered in Atlanta and Alpharetta, is a fully licensed and insured metal roof coating company. We are a manufacturer certified installer of new acrylic, elastomeric, urethane, silicone and aluminum metal roof coating products. We are the #1 rated roofing contractor of choice when it comes to extending the lifespan of your existing metal roof or installing new roof coating products.

Benifets of a New Metal Roof Coating

- Provides a seamless, durable membrane

- Offers superior adhesion to various substrates

- Contains fungicides and mildewcides

- Boasts excellent UV protection for polyurethane foam

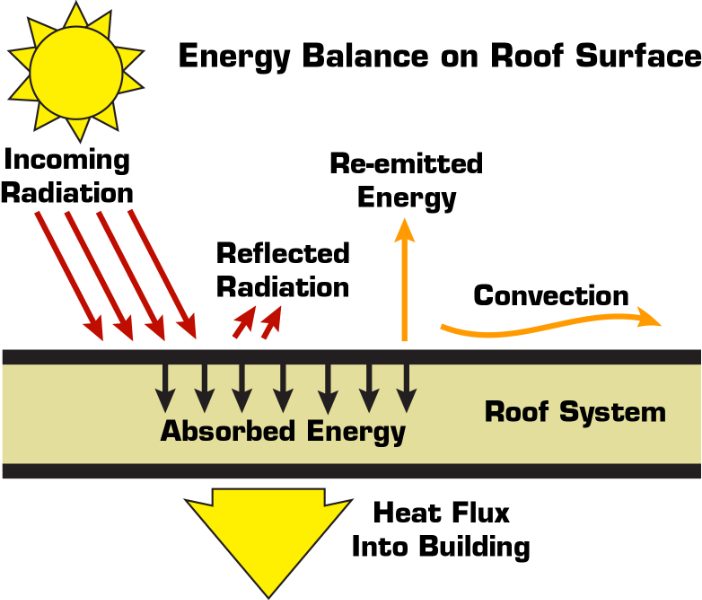

- Energy Star Rated – Heat reflective coating helps reduce cooling costs

- Reflects the sun’s UV-rays with LEED Certified products

- Prevents premature roof failure by controlling thermal cycling

- Easy-to-use, non-toxic, and VOC-compliant water based coating

- Fully tax deductible in first year vs. depreciating new roof construction over a number of years

- Lifetime warranties available that are renewable every ten years

- Cost-efficient

- Extends the overall life of metal roofing systems

Our Installation process

- All surfaces to be coated must be clean, dry, and free of any oil, grease, dirt, and rust

- Any existing coating must be checked for good adhesion

- Before application, any loosely adhered coating must be removed and bare surfaces must be prepared

- Products must be cleaned and checked for compatibility

- Rated elastomeric roofing products come ready to use – thinning is not recommended

- Containers should not be left open for extended periods of time

- Follow our roof restoration procedures and always perform a coating adhesion test before applying the product to the entire roof

- If you use a spray, use a 1 gpm Airless Sprayer with a 3,000 psi and a .027 or .031 tip

- Opt for a high-quality synthetic bristle brush

- Use a short nap roller

- Clean up using water

Metal Coating Repair Maintenance

GA Roofing & Repair, Inc. will schedule periodic metal roof coating repair and maintenance to your existing system to ensure an extend the service life and reliable reflectivity.

Metal Roof Coating Systems History

In 1991, the Committee on Science, Engineering, and Public Policy of the National Academy of Sciences, the National Academy of Engineering, and the Institute of Medicine published a report titled Policy Implications of Greenhouse Warming. One mitigation option in their findings was the use of “white surfaces” “… to reduce air conditioning use and the urban heat island effect by 25% through planting vegetation and painting roofs white at 50% of U.S. residences.”

Dow Construction Chemicals has been investigating the use of white acrylic roof coatings to reduce air conditioning demand since 1981. Early “bird house” experiments conducted by Rohm and Haas Company (now a wholly owned subsidiary of The Dow chemical Company) clearly demonstrated that white elastomeric roof coatings could reduce the internal temperature of uninsulated and poorly ventilated buildings quite significantly. Moreover, these coatings could prolong the life of a roof by protecting the asphalt roofing material below from degradation that results from exposure to heat, sunlight, water, and thermal shock. It became readily apparent that the degree of dirt pickup resistance had a dramatic effect on the solar reflective and, ultimately, the air conditioning demand.

Simply stated, the longer the metal roof coating retained its white appearance, the better its effect in reducing the building heat load. To quantify this, a novel laboratory technique was developed to predict the relative dirt pickup of typical reflective coatings. In cooperation with Mississippi Power Company and the University of Southern Mississippi, we conducted a series of comprehensive full-scale studies on actual buildings to quantify the effect of these elastomeric coatings on reducing air conditioning demand. A secondary objective was to determine the “energy penalty” associated with heating a thermally reflective coated building versus a similar building covered with a conventional black asphalt roof. The study showed that the coating reduced the peak air conditioning energy demand by 25%. The cost of coating and labor could be amortized in approximately two years. The energy penalty was minimal in this study. The then-current (1994) laboratory specifications for manufactured acrylic roof coatings and a technique for assessing surface reflectivity and dirt pickup resistance were also documented.

call us at!